STUB END | LAP JOINT CARBON,ALLOY, STAINLESS STEEL LONG/SHORT PATTERN STUB ENDS/LAP JOINTS

Stub End/Lap Joint Production Range

Type : Long/ Short Lap Joint Stub End

TOutsideDiameter:1/2″– 24″

Wall Thickness: 2mm – 100 mm / SCH5, SCH10,SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH120, SCH140, SCH160, XXS

Production Grades: Stainless Steel, AlloySteel, Duplex, Nickel Alloys, Low temperature Steel, Carbon Steel, Cupronickel

Standards

ASME: ANSI B16.9, ANSIB16.28, MSS-SP-43

DIN: DIN2605, DIN2615, DIN2616, DIN2617, DIN28011

EN: EN10253-1, EN10253-2

ASTM A403 – ASME SA403 – StandardSpecification for Wrought Austenitic Stainless Steel Piping Fittings

ASME B16.9 – Factory-Made Wrought Fittings Butt-welding

ASME B16.25 – Butt-welding Ends ASME B16.28 – Wrought SteelShort Radius Elbows and Butt-welding Returns

MSS SP-43 – Wrought and Fabricated Butt-Welding Fittings forLow Pressure, Corrosion Resistant Applications

Stub Ends Material Grades

Stainless Steel Stub End:ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

Carbon Steel Stub End:ASTM A 234 WPB , WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY70.

Low Temperature Carbon Steel Stub End:ASTM A420 WPL3, A420 WPL6

Alloy Steel Stub End: ASTM /ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

Duplex Steel Stub End: ASTM A 815, ASME SA 815 UNS NO S31803, S32205. Material No. 1.4462

Nickel Alloy Stub End:

ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400(MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600(INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 (HASTELLOY C 276 )

Stainless stub end are fittings used in place of welded flanges where rotating back up flanges are desired.

They are also called Lap Joints and Vanstone Flared Laps. A rotating back up flange seats itself against the back surface of the Stub End. When bolts are added, the clamping action of the bolts presses the rotating back up flange against the back of the Stub End. The gasket surface of the Stub End then presses against a gasket and another gasket surface providing joints like standard flange joints.

The seal is made by the gasket surface of the stub end alone, the flange only provides the clamping pressure on the joint.

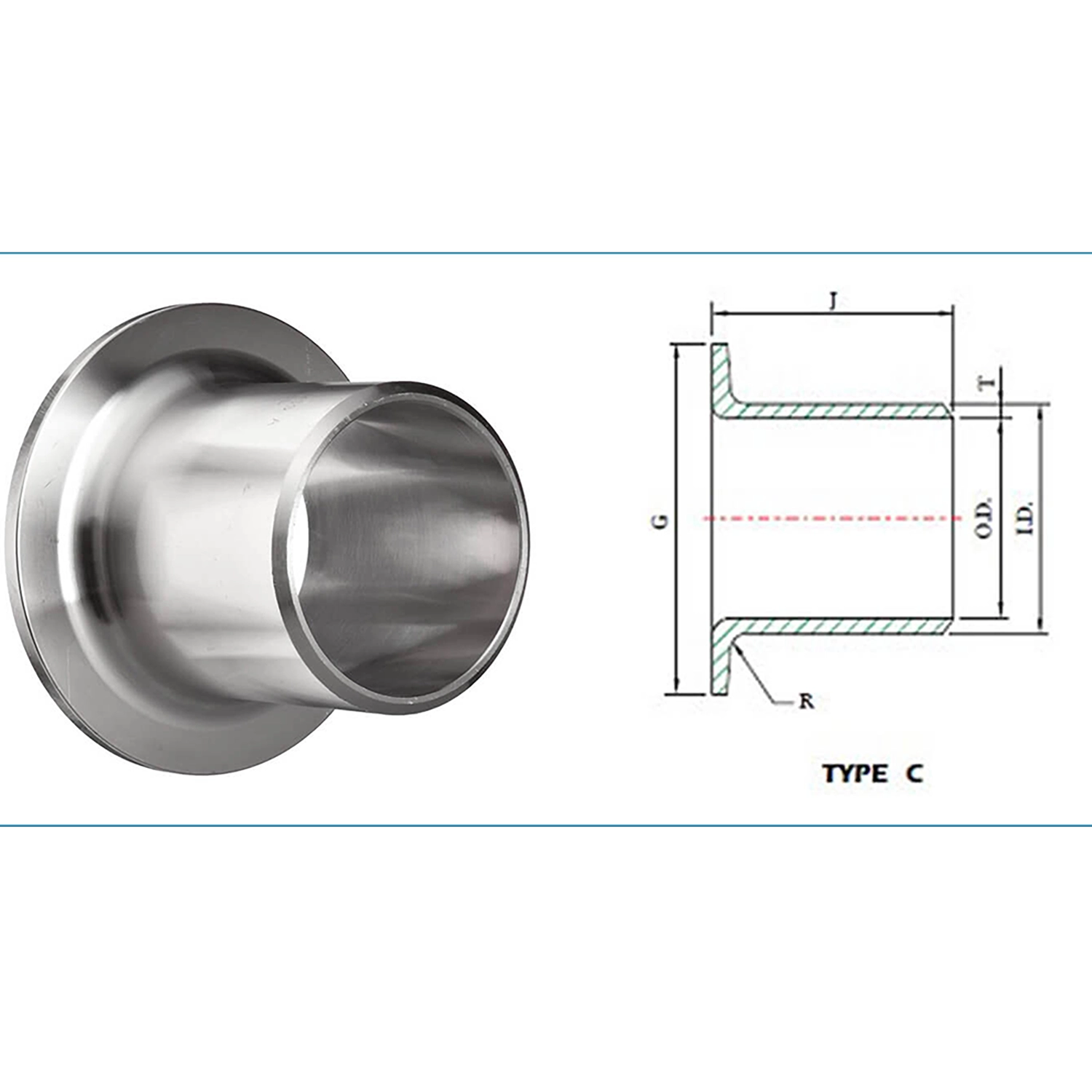

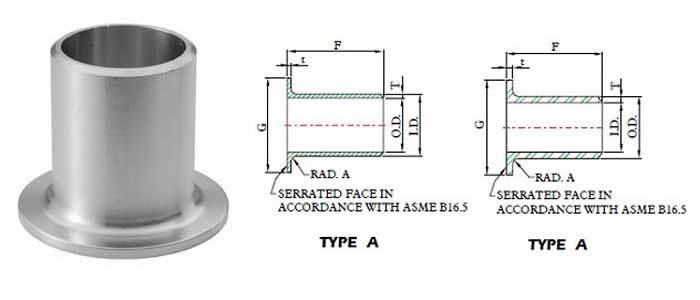

There are three different types of stub ends, Type A, B and C. Type A stub ends are machined to fit in a standard lap joint backing flange

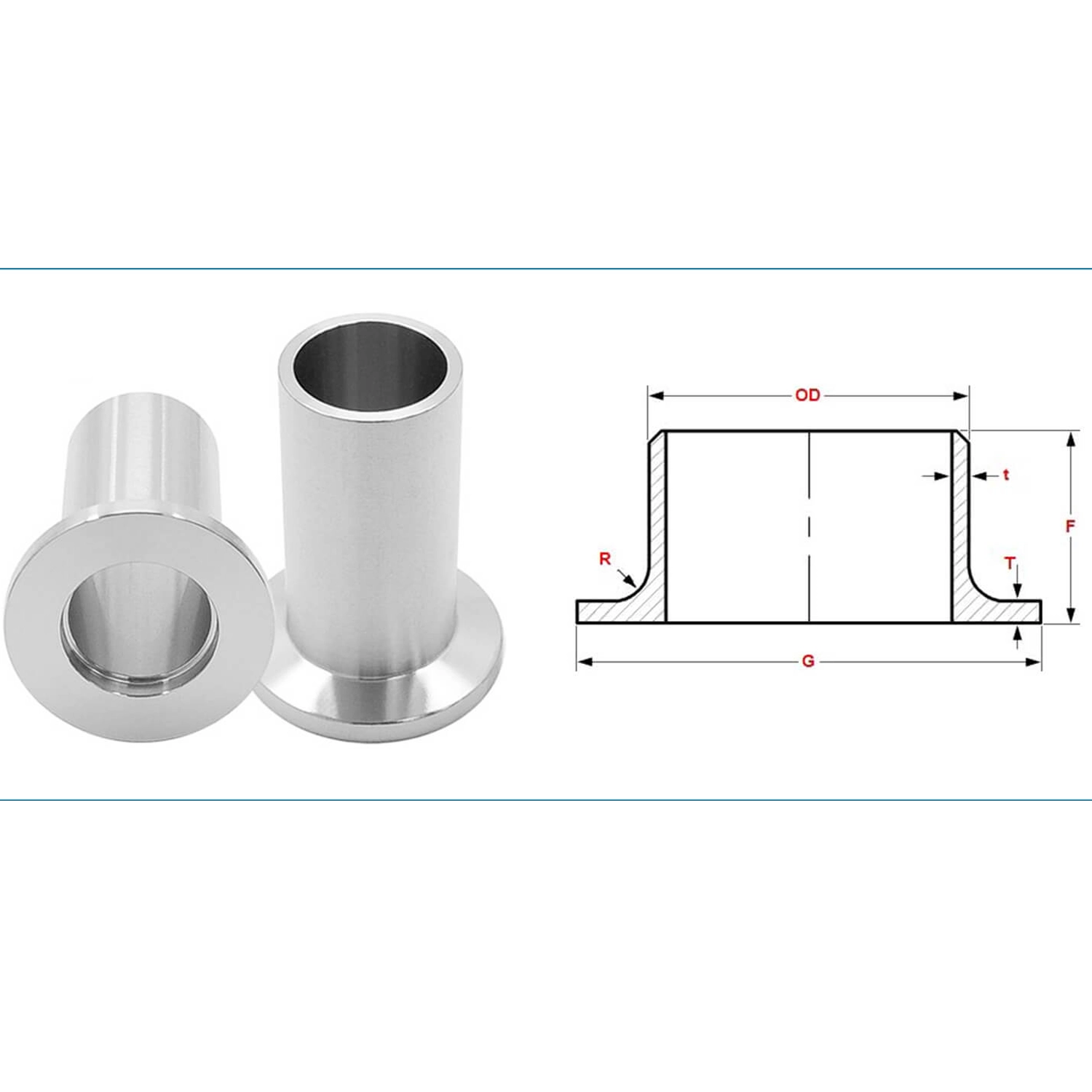

ASME B16.9 Stub End Dimensions

Application:

Petroleum, Chemical, Power, Gas, Metallurgy, Ship-building, Construction, ect.